Category: Modular Furniture Design | Focus: Parametric Design & CNC Fabrication

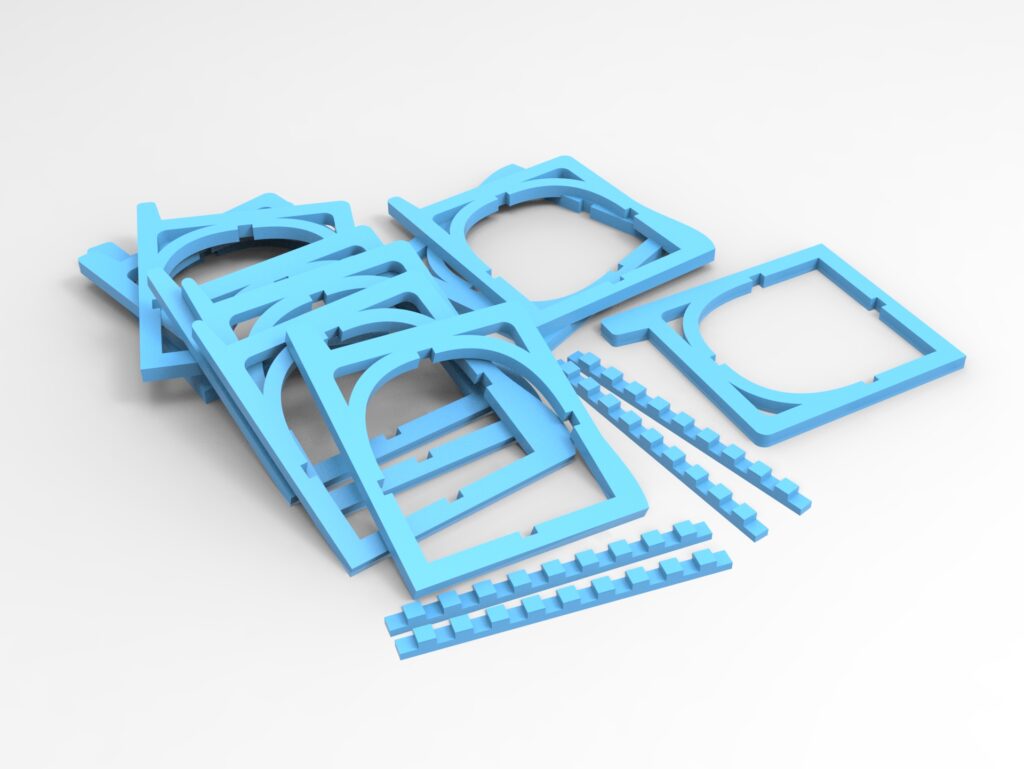

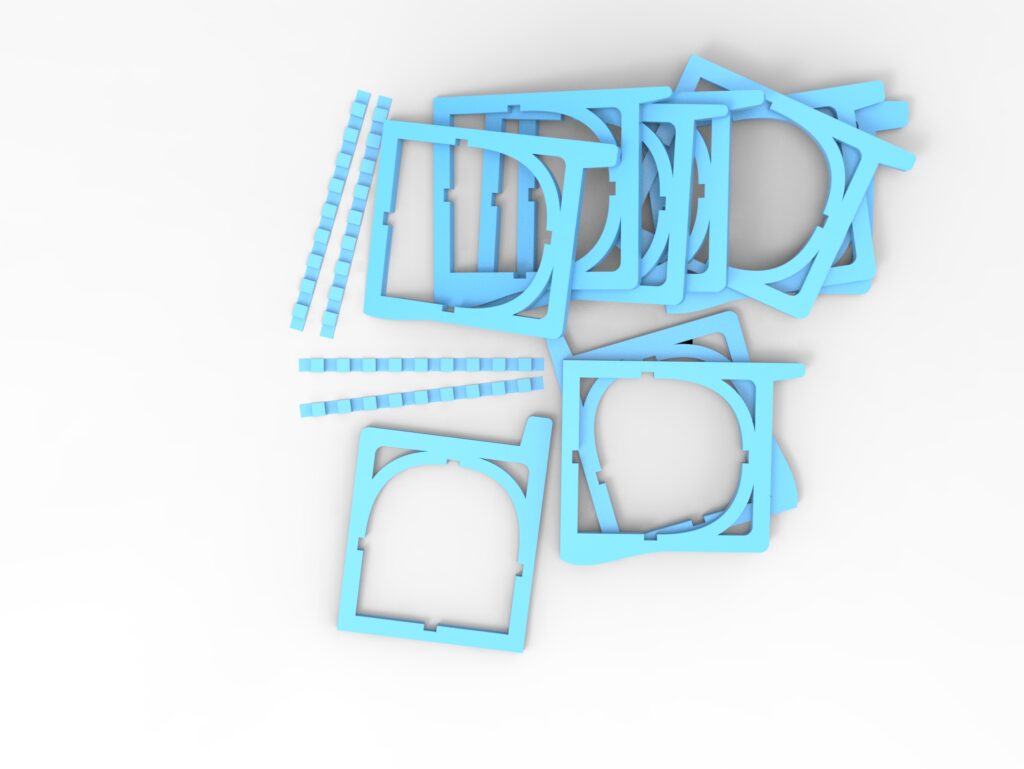

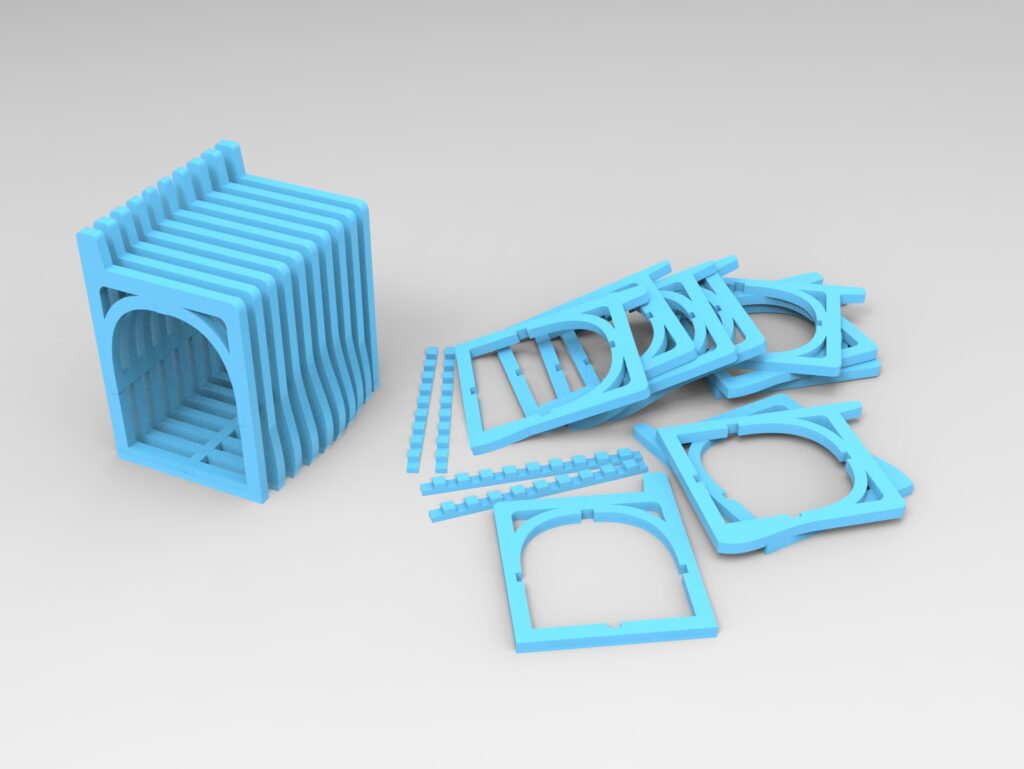

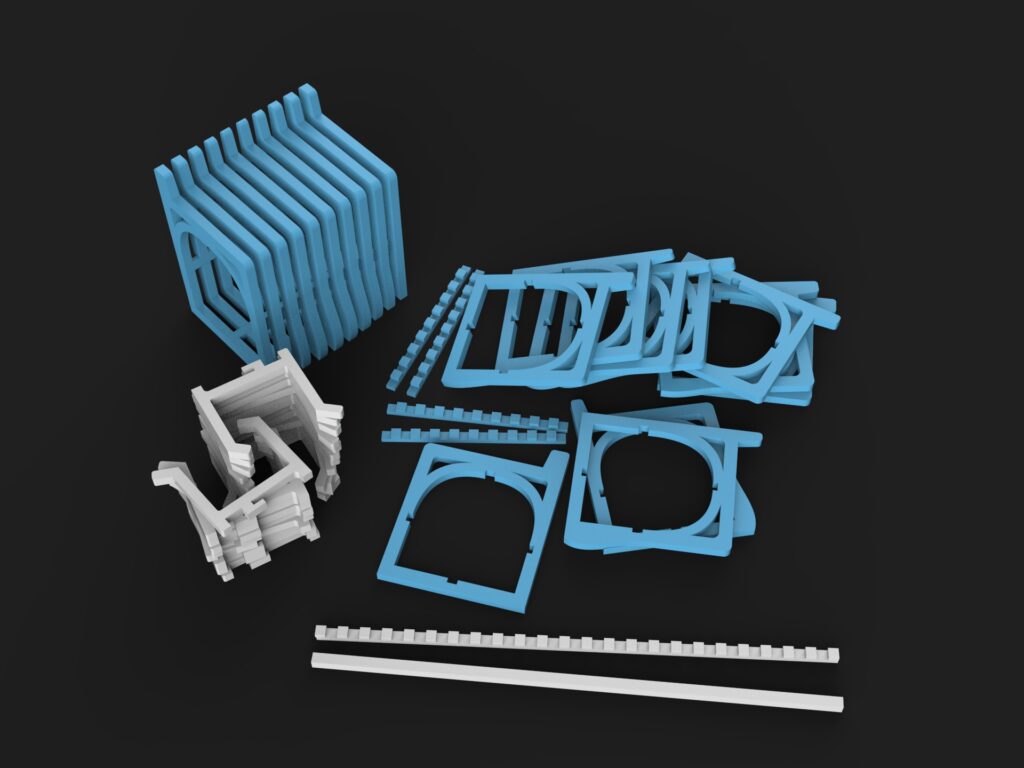

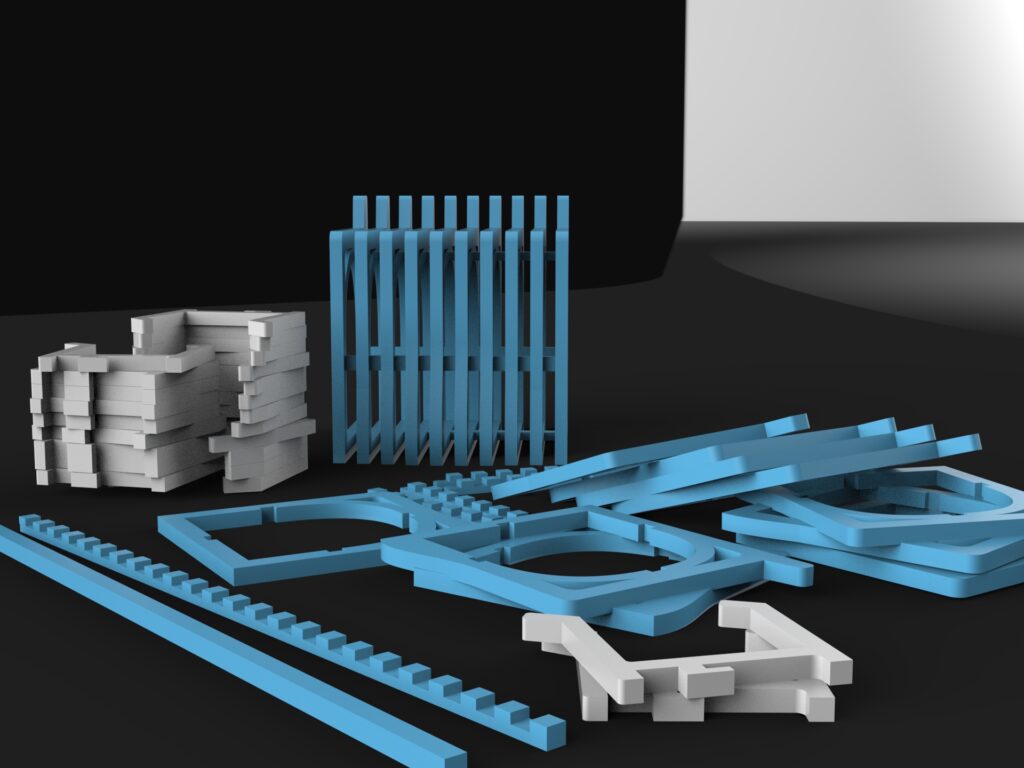

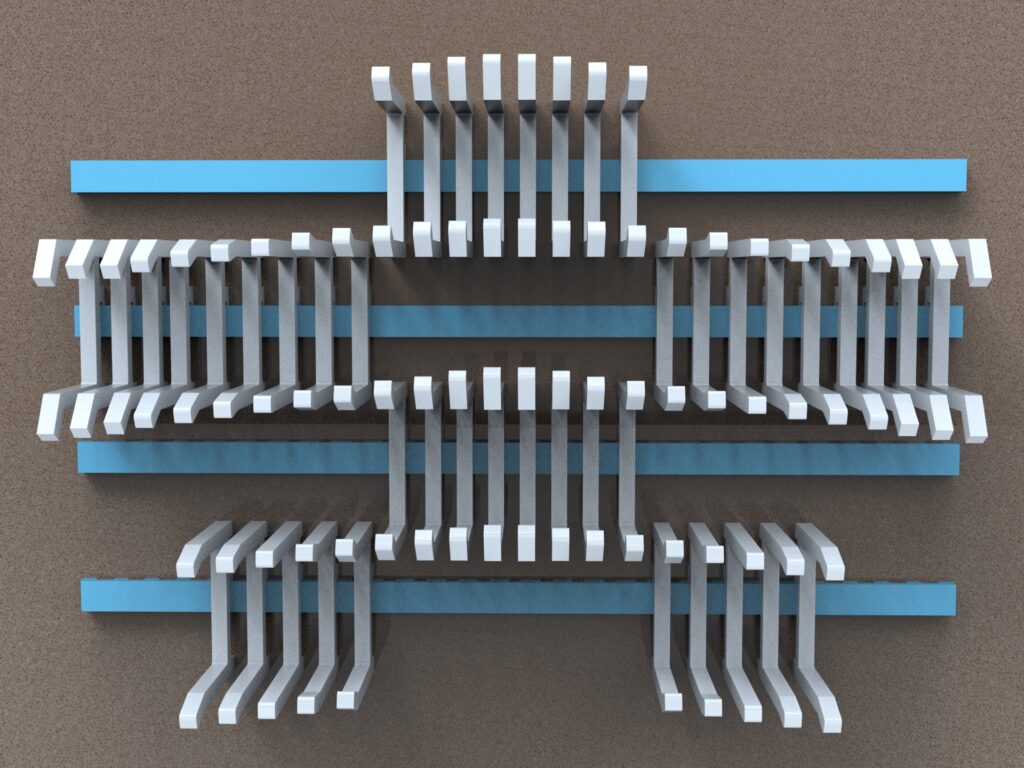

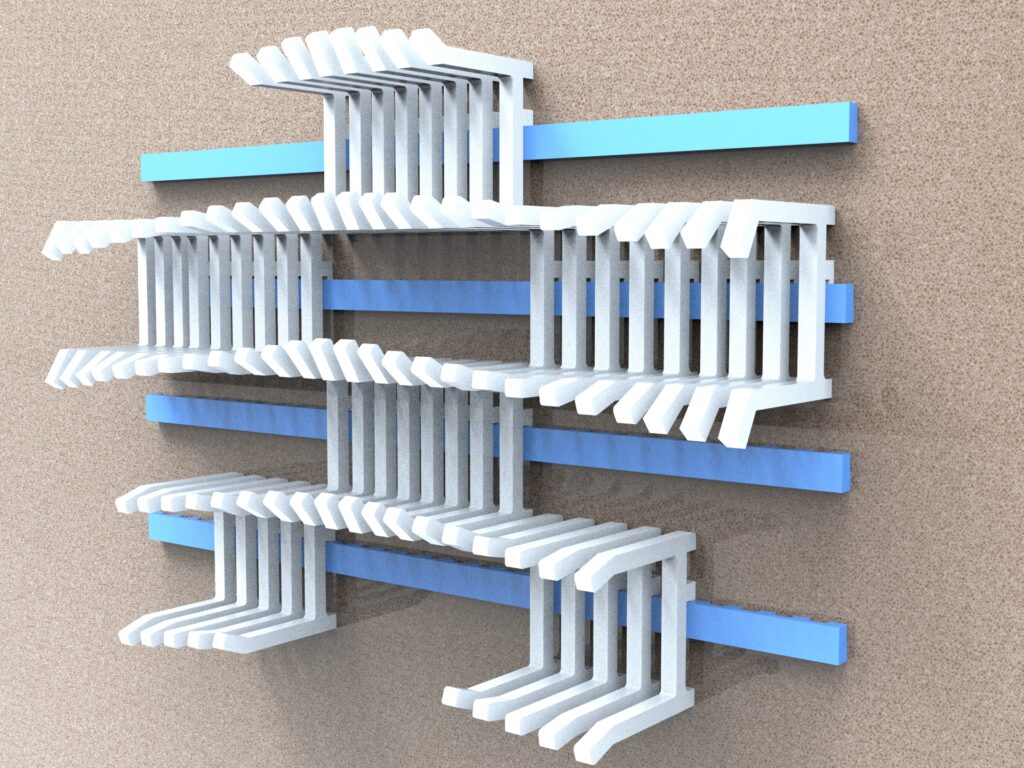

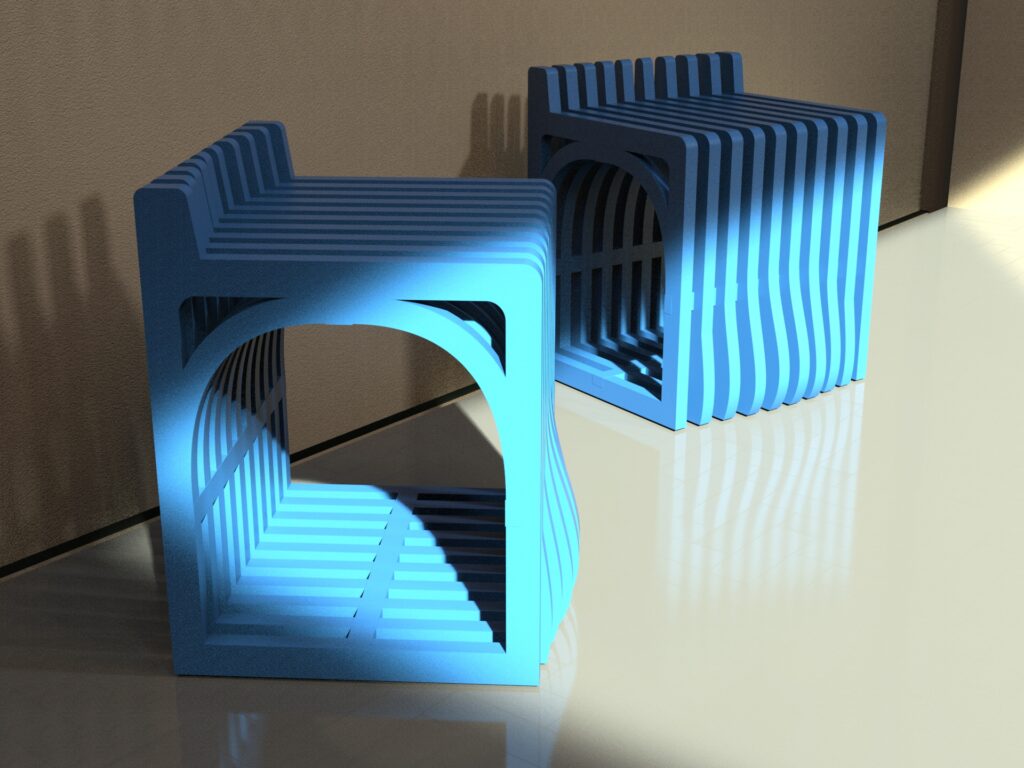

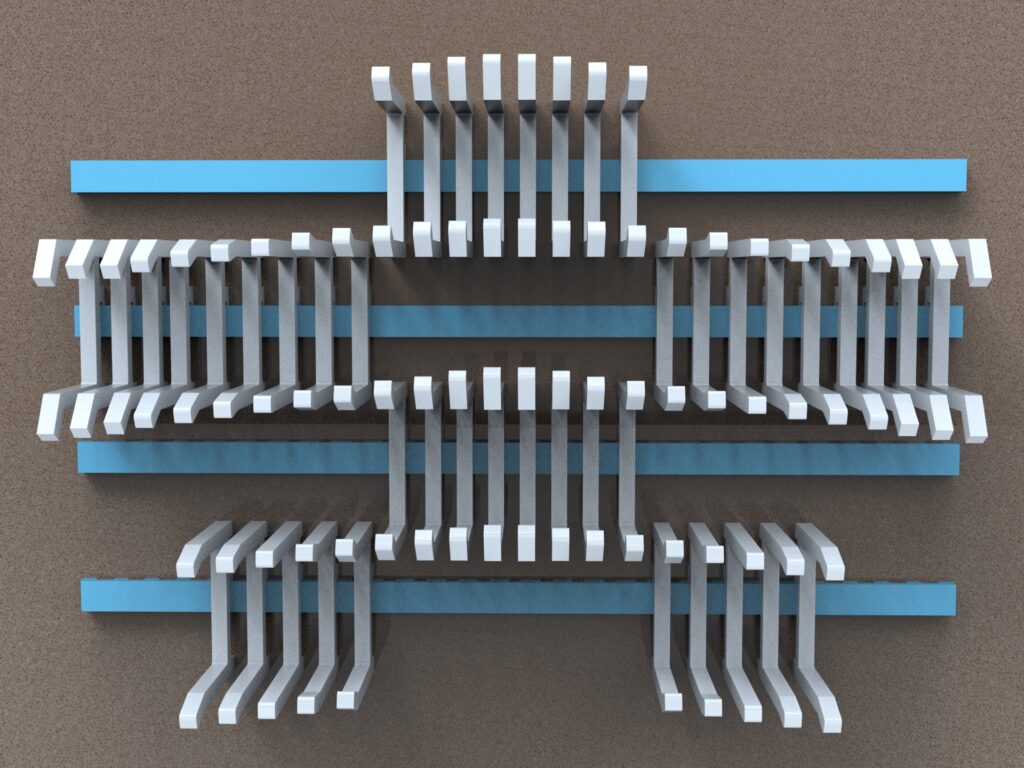

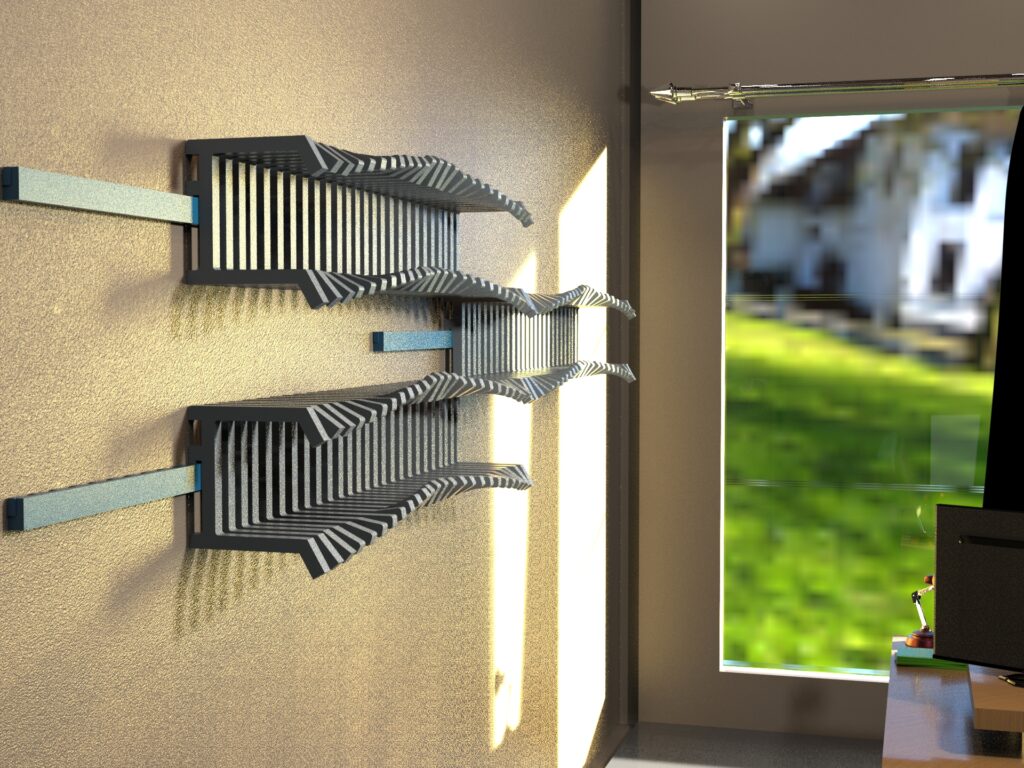

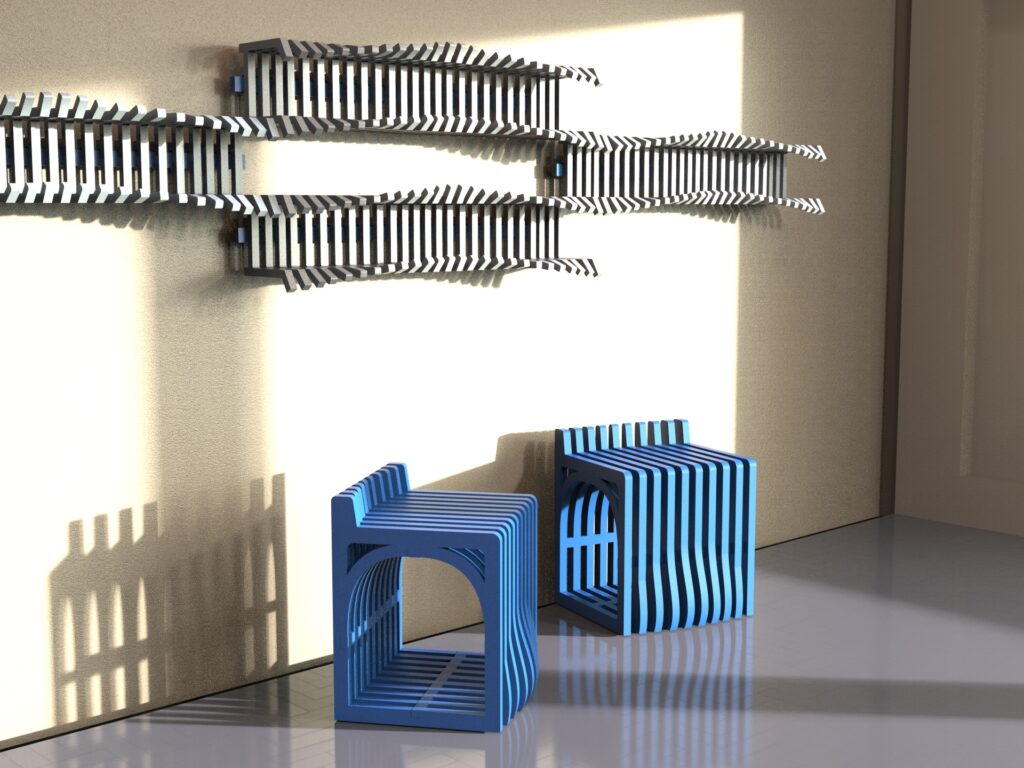

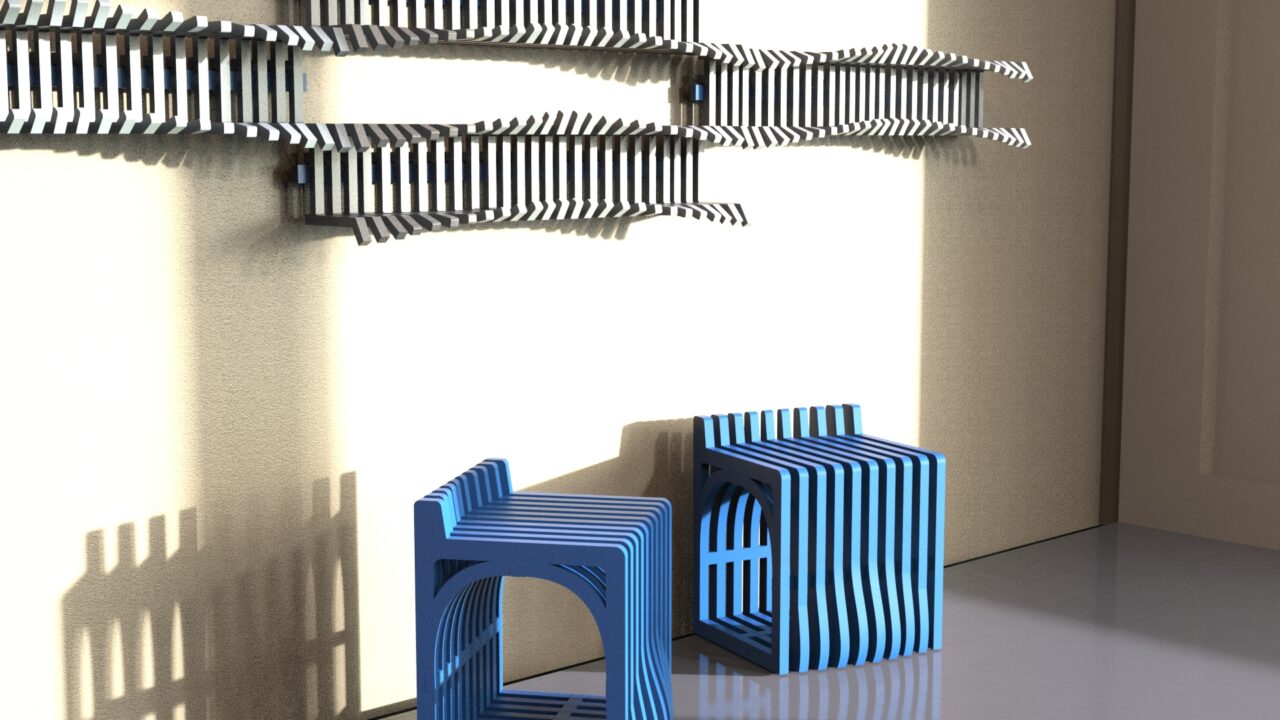

This project showcases the development of a modular wall-mounted shelving system and multi-purpose furniture units through CNC cutting techniques. Designed with both aesthetics and manufacturing efficiency in mind, the system emphasizes flat-pack assembly, interlocking joints, and minimal material wastage.

🔷 Objective:

To create a scalable furniture system using parametric design logic, suitable for CNC routing on plywood sheets, enabling easy transport, assembly, and customization.

🔷 Design Highlights:

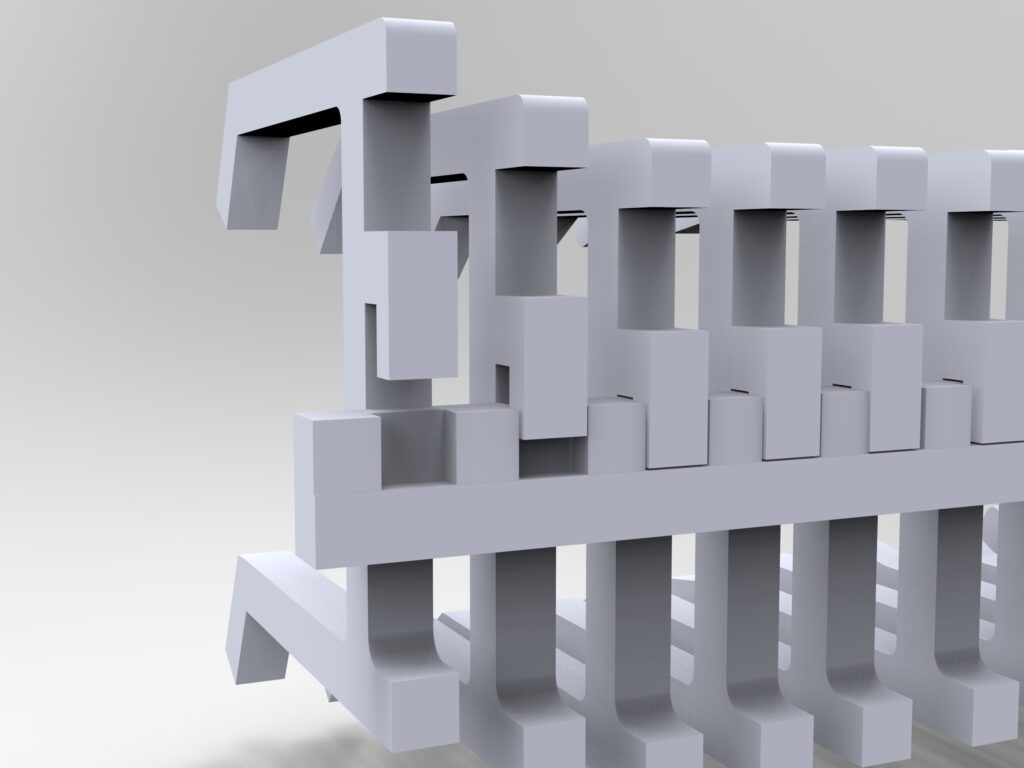

- Modular Slot-Fit System: Pieces are precision-cut to interlock without nails or glue, supporting flat-pack transport.

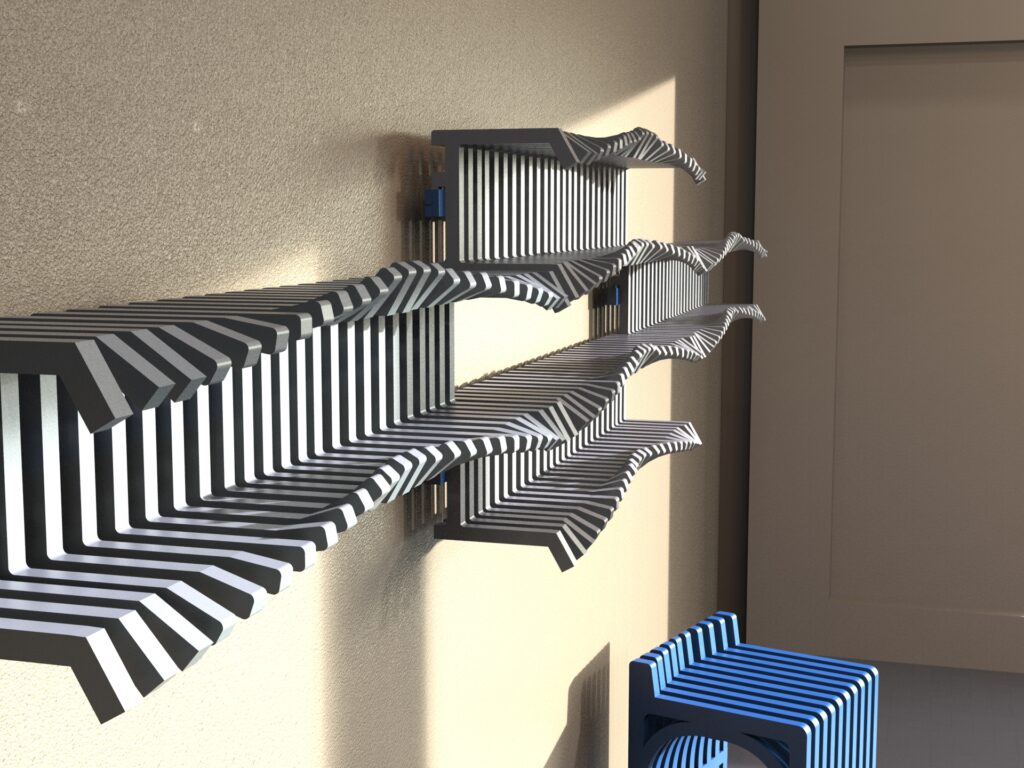

- Wall Integration: The shelving units mount onto rods or walls with layered components, offering depth and rhythm.

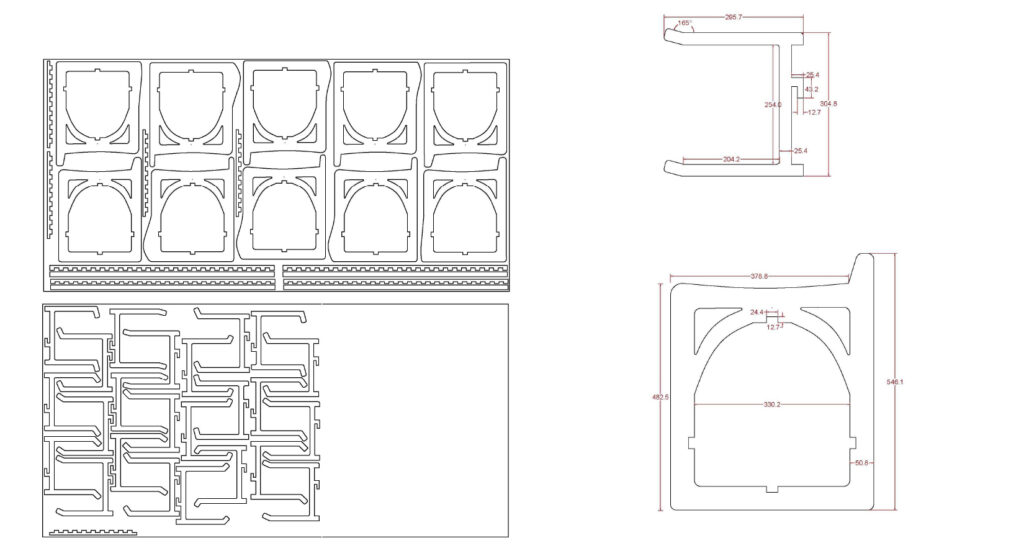

- Optimized Material Use: Cutting layout planned on an 8×4 ft sheet to reduce waste.

- Expandable Design: The form can be extended or reduced based on spatial needs.

- 3D Prototyping: Rendered views and exploded diagrams were created to validate the build process.

🛠️ Tools & Techniques:

- AutoCAD & Rhino/3ds Max – For precision modeling and drafting

- CNC Sheet Layout Planning – Efficient nesting and scaling

- Rendering Software – For final visual presentation

- Physical Prototyping Logic – Components designed with fabrication constraints in mind

This project reflects Tabish’s command of digital fabrication, precision design, and the integration of form with function, making it ideal for both commercial and residential environments.